The JAG SHIELD plate and shell heat exchanger represents a new, revolutionary solution, ensuring not only increased flow turbulence, but also extensive heat exchange area.

The shell and plate heat exchangers, as an alternative to shell and tube exchangers, are perfect for working at high pressure (up to 100 bar) and high temperature (up to 450˚C). The design of the new JAG SHIELD allowed for more compact, lighter, and above all more efficient exchanger, perfectly adjusting to individual requirements. The special shape of heating plates and the use of innovative JAG corrugation pattern resulted in high thermal effectiveness, while maintaining low flow resistance.

The new “jagged” channel design creates a more turbulent flow, which improves heat exchange and also decreases sediment accumulation. The additional benefit is an extensive heat exchange area and decreased overall pressure drops. Highly efficient JAG SHIELD plate and shell heat exchangers provide a reliable solution for applications requiring high working pressure. They serve as evaporators or condensers in refrigeration, as oil coolers or heaters, and in CIP cleaning systems. They are perfect for steam heating or condensing processes. The exchangers made of stainless steel, Hastelloy or Incolloy superalloys may also work with aggressive media.

Features

-

innovative JAG heating plates corrugations patternincreases thermal effectiveness of the exchanger

-

Special shape of the heater platessignificantly decreases local flow resistance

-

Vacuum solderingused to join plates in pairs, ensures highly durable design, with substantial resistance to variable thermal loading and stress

-

Optimized utilization of the exchanger volumeallows to decrease its size

-

Design resistant to high pressure(up to 100 bar) and temperature (up to 450˚C)

-

Compact sizeallows to save space

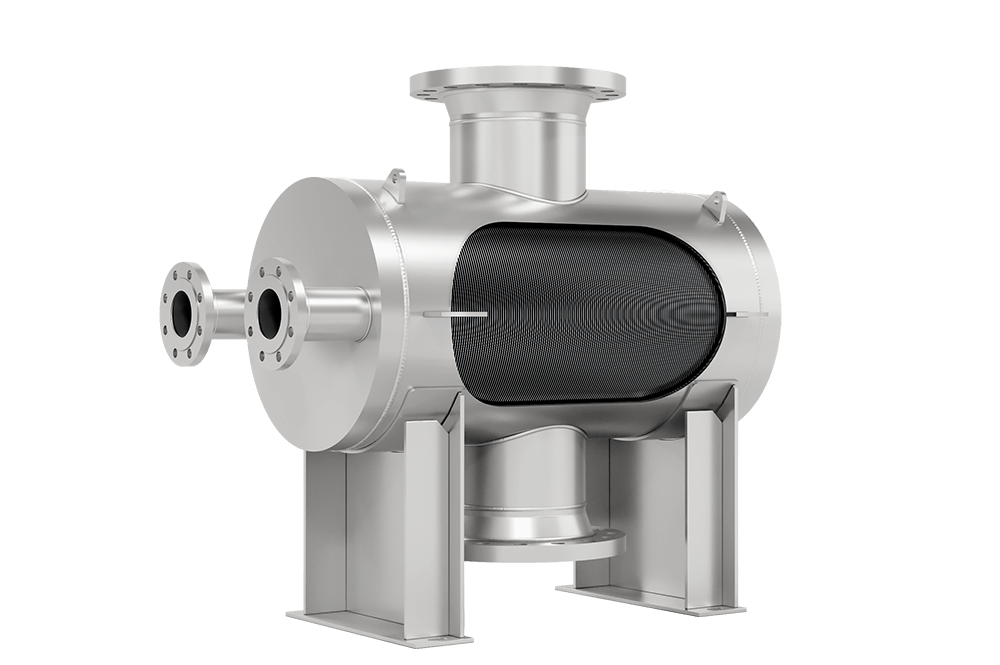

Design

-

Shell

-

Heating plates pack

-

Plate side connections

-

Shell side connections

-

Mounts

-

Lifting lugs

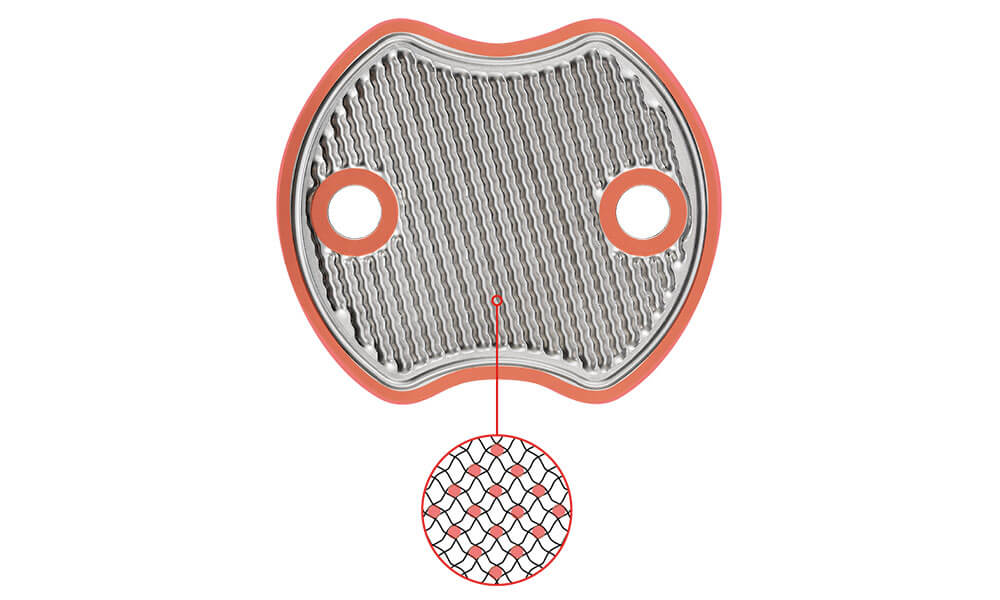

Brazing instead of welding

Vacuum brazing, used to join plates in pairs, as opposed to more popular circumferential welding, allows for significantly larger connection surface. A pair of plates is connected on the entire external circumference, on ports and additionally on many optimally selected heat exchange surface points. The result is highly durable design, with substantial resistance to variable thermal loading and stress. This makes the exchanger highly reliable and airtight. Copper, LUNATM stainless, and other brazing materials allow for using the JAG SHIELD heat exchangers in various applications.

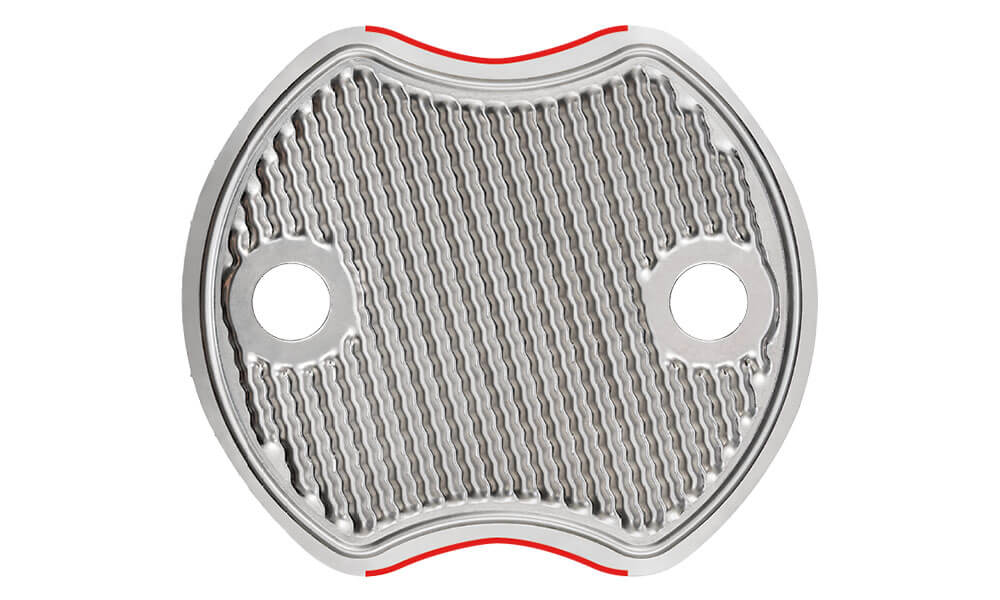

Unique plate shape

The shape of the JAG SHIELD plate ensures exceptional thermal effectiveness, while maintaining low flow resistance. Thanks to the special shape of plates, the flow directors are not necessary, as the medium is distributed evenly between the plates. Side notches ensure enough space for the shell medium to properly fill its entire space. The unique shape also significantly decreases local flow resistance. Optimized utilization of the exchanger volume allows to decrease its size. Additional corrugations on the circumference of heating plates stabilizes the pack and optimizes the stress, ensuring longer life span.