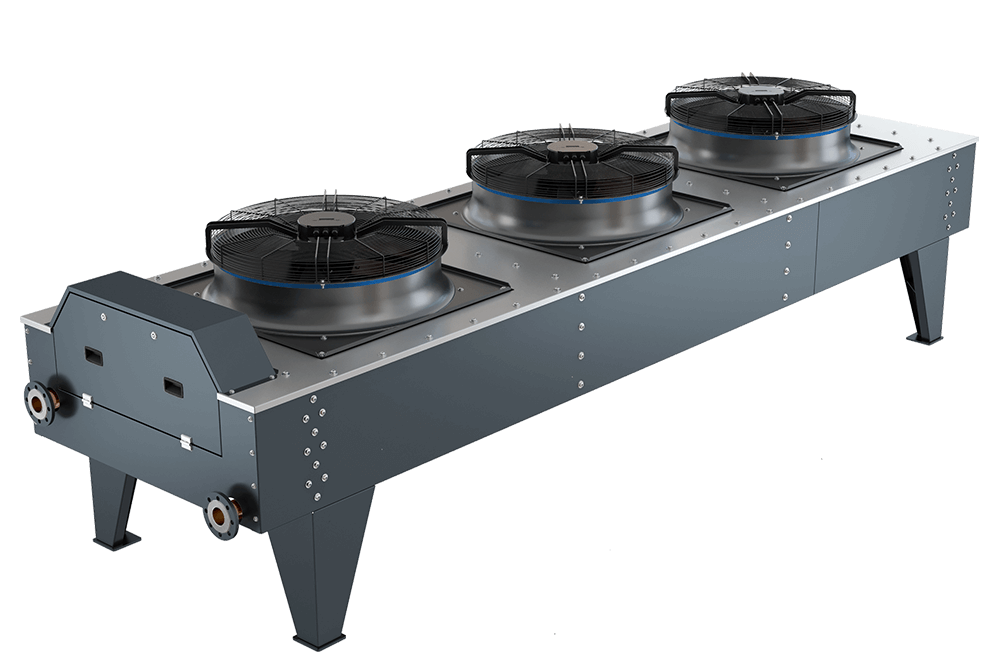

Dry coolers are used to cool industrial systems, as well as industrial and commercial facilities.

The process consists in dumping excess heat to the environment, if its utilization is not economically justifiable. They operate by cooling the fluid passing through the tubes inside the finned heat exchanger with fans-generated air flow.

Fluid cooling using dry coolers is the cheapest method for dispersing waste heat, as they reach high performance at minimum power consumption.

Features

-

Efficient cooling methodfor industrial systems, as well as industrial and commercial facilities

-

Cheapest waste heat dispersion method

-

High performance at minimum power consumption

-

Closed-circuit system operationno contamination or excessive water consumption

-

Ability to use various mediawater, glycol solutions, oils etc.

-

High durability of the key componentssuch as heat exchanger, fans and electronic components

-

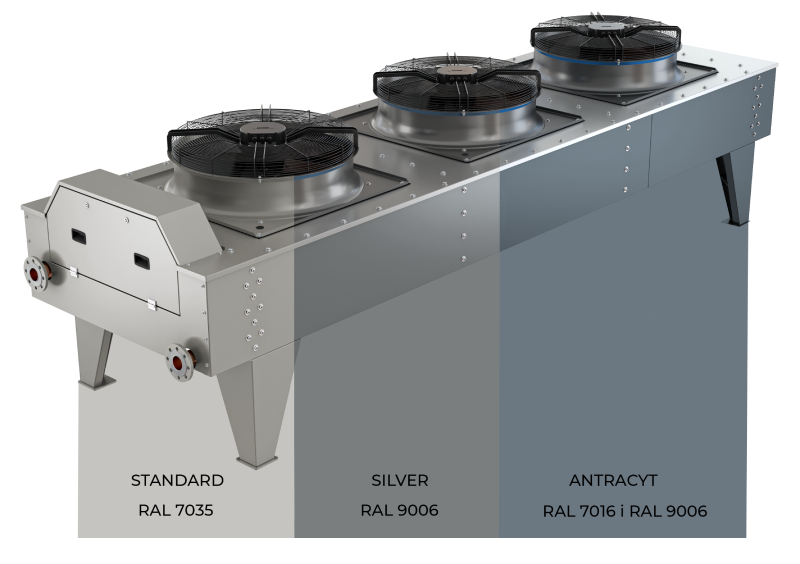

Available in three color versions

-

Low noise level: starting from <40 dB

Design

-

Coversmade of thick wet-painted or powder-coated galvanized carbon steel in three color versions

-

Baffle/tube connections stabilization systemincreasing the life expectancy of the device

Baffle/tube connections stabilization systemincreasing the life expectancy of the device

-

Fans

-

Fin exchanger

Fin exchanger

Dry cooler

Fans

- maintenance-free, among the most silent on the market, axial fans with low noise levels, starting from as low as <40 dBa

- 30% lower electricity consumption

- EC and AC motors

- meet the requirements of the ERP 2015 Directive

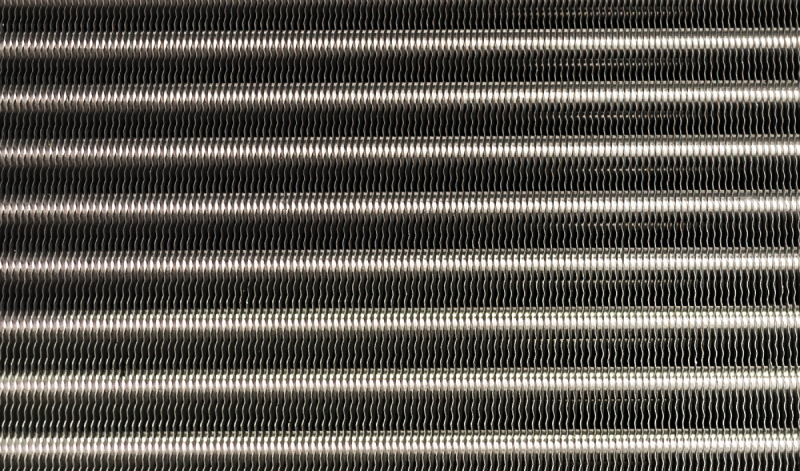

Fin Exchanger

- copper tubes Ø 12 mm

- aluminum fins

- fin distance 2.1 mm, 2.3 mm or 2.5 mm, depending on the specific application

- baffle/tube connection stabilization system, improving the life span of the device

- copper components brazed with high silver content material

Color versions

Three color versions allow for adjusting the dry cooler color as needed.

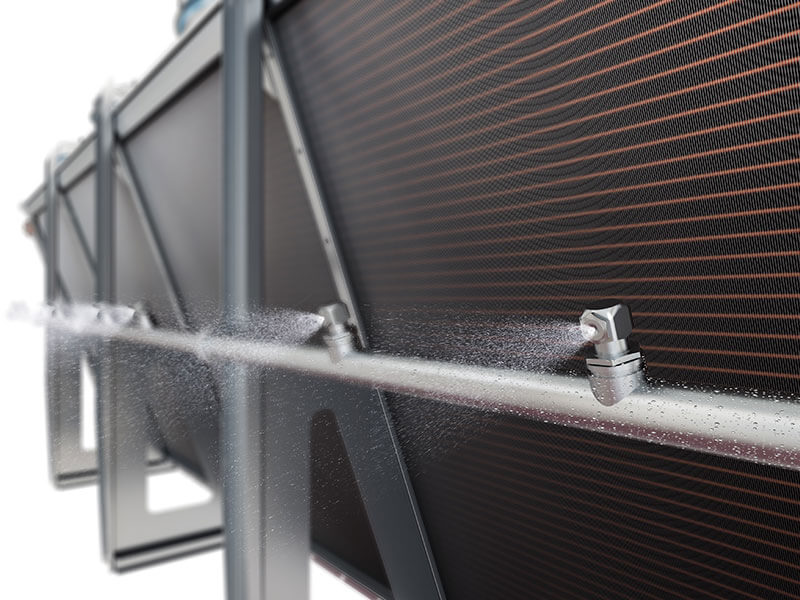

Adiabatic system

allows the device to operate even when the air temperature is higher than the fluid temperature, if the air humidity is adequately low.