DNA heat exchangers constitute another step in the evolution of shell and tube exchangers. They provide a number of hydraulic and heat exchange improvements, preserving the features and benefits of the traditional design.

DNA reaches a significantly higher heat exchange coefficient compared to standard solutions. Distribution of the tubes in the shell allows for more efficient operation in high flow installation (e.g. exhaust, hot air, low pressure steam). Thanks to its unique tube side design, the DNA exchanger is compatible with high-viscosity media, retaining a high level of heat exchange.

The unique design of the DNA exchanger allowed for a lower and lighter device, made with significant saving of material, at the same time preserving high mechanical resistance characteristic for shell and tube exchangers.

Features

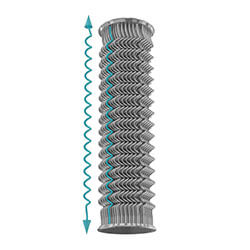

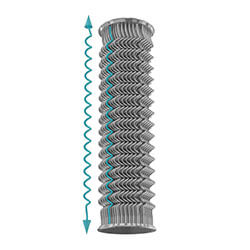

- Spiral tubes ensure turbulent rotational flow, which doubles the heat exchange coefficient.

- Low pressure drops and lack of dead zones

- Extensive heat exchange surface in compact heat exchangers

- Ideal for operation with high-flow media

- Made entirely of stainless steel, corrosion resistant

- Possibility to make the exchanger from titanium resistant to aggressive substances

Design

-

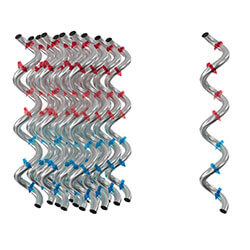

Helicoidal Ø 10 mm tubesensuring a turbulent rotational flow, increasing the heat exchange

Helicoidal Ø 10 mm tubesensuring a turbulent rotational flow, increasing the heat exchange

-

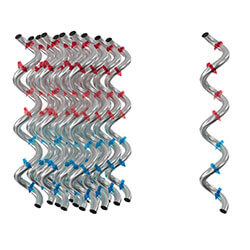

Stress-compensating tube packageEliminating vibration thanks to a large amount of contact points along the tube pack without the need to use baffles or shell compensator

Stress-compensating tube packageEliminating vibration thanks to a large amount of contact points along the tube pack without the need to use baffles or shell compensator

-

Expanded heat exchange areawith an equal distribution of flow and velocity

Expanded heat exchange areawith an equal distribution of flow and velocity

-

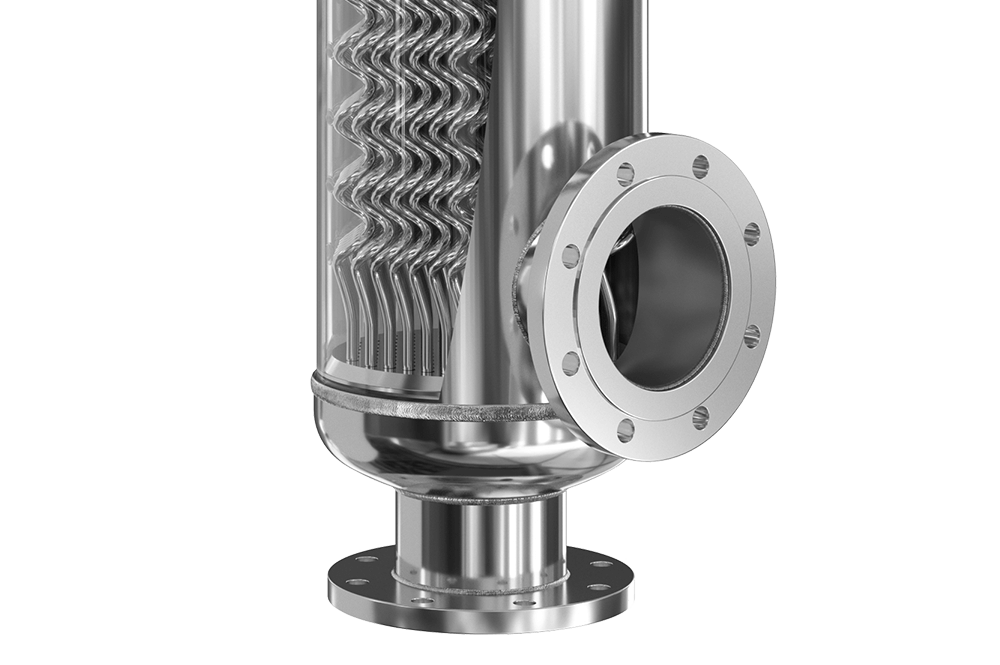

Flanged connections

Flanged connections

-

Shell

-

Dished head

DNA

For over 30 years, HEXONIC has been improving its products, in order for you to be certain of the best choice available on the market.